- CompAir Air Compressor Manuals. Owners manuals for CompAir Air Compressors available to download in Adobe.pdf format. Assembly, operation and maintenance instructions with exploded parts list and diagram. Product Name+: Price: Buy Now: Cyclon 105 Rotary Screw Air Compressor Manual: $4.95.

- COMPRESSOR COMPAIR L37 FOR SALE WWW.USED-MACHINETOOL.COM -YEAR 2007 NHz 50 Model L37 Series L Series Description Lubricated Screw (L Series) Gas Compressed.

- COMPAIR’S ENERGY SAVING MACHINES. Frame 3 L30, L37, L45, L45PRO. Reliable operation and protects your investment.

- Manual Compair L37 is the eighth story in the Harry Potter series and the fir Manual Compair L37. Get free kindle Manual Compair L37 or download adn read online kindle Manual Compair L37 ebook. Download ePub In wiki says that Manual Compair L37 is supposed to have 320 pages. Step 2) Tried to read the book after.

- Compair l22 service manual Compair l22 service manual The l22 secrets of studio behind of how to manage your. CompAir L07-L22; CompAir L30-L132; Rotary Screw.

- The high output compression element on the CompAir L37 air compressor has a slow rotational speed, reducing energy costs. To all service points for short servicing times and reduced service costs. CompAir L30-L45 range brochure.

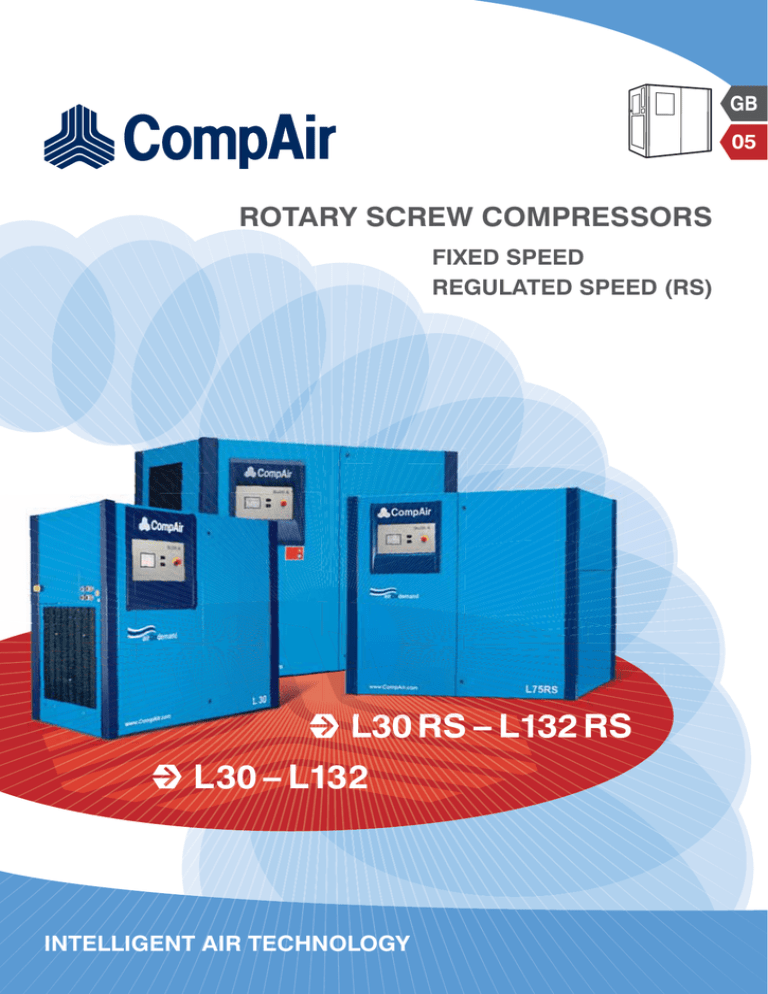

All CompAir rotary screw compressors can be sized to suit the required output, and can be driven by either a fixed speed drive motor or our variable speed drive system. The volume flow can be precisely controlled to meet your continually changing demands. This ensures that you use only the energy required to do the job and no more. CompAir L02 - L05 Thanks to the user-friendly design of the L02-L05 range these compressors are ready for plug & play operation. Maintenance is made easy by the removable side doors providing you with quick and easy access to all service points.

Search in COMPAIR catalogs and technical brochures on DirectIndustry and find the information you need in 1 click.

Warning or maintenance as described in the following chapters - 8.3.4 to 8.3.9. Equipment without CompAir DEMAG's prior permission.

The simple design minimises the number of moving parts and as a result reliability is increased and maintenance costs reduced. CompAir L07 - L22 The new design of the high efficiency airend operates at low rotational speeds, and as a result lowers energy costs. The innovative integrated design, with oil separation, oil filter, thermostatic bypass valve, reduces the number of external hoses and components resulting in increased reliability. CompAir L23 - L29 The high output compression element with slow rotational speed reduces energy costs. In addition to this, the innovative design of the failsafe shaft seal, integrated oil filter and oil regulation valve, ensures external hoses are reduced to a minimum to guarantee the highest levels of quality and reliability are achieved. Two stage filtration ensures highest quality air is delivered to your system at less than 3ppm oil carryover. The vessel has a hinged cover for easy maintenance.

Service Manual Kia

All models are available with an integrated dryer. This option comes complete with a dryer and water separator, both fitted with zero loss drains, to eliminate expensive air loss and maximise energy efficiency. Thanks to ESD control the dryer only consumes energy when the system actually needs compressed air – unlike conventional dryers which continue to consume energy even when the system is off load. These features not only save energy but considerably enhance the reliability of the compressed air supply.

CompAir L30 - L132 Operating using slower rotation speed in the air end rotors, equipped with a 2-pole TEFC IP 55 energy-saving CEMEP CLASS EFF1 high efficiency motor and fitted with a modified, premium efficiency air end - these new compressors can deliver energy savings of up to 7.2% compared to other manufacturers. This can cut energy bills by up to £1,000 per year and reduce annual CO 2 emissions by up to 9,000kg, making a positive impact on both the bottom line and the environment. CompAir L160 - L250 A high capacity air compressor range that sets the highest standards in reliable, economical and efficient operation. Screw compression elements are manufactured in-house using the latest CNC rotor grinding machinery, coupled with on-line laser technology, in order to maintain precise manufacturing tolerances. The resulting reliability and performance ensure that operating costs will remain low throughout the compressor’s life. The innovative compressor design saves unnecessary service costs.

Service Manual Troy-bilt

All component parts are designed for a long service life and the generously-sized suction filters, oil filters and fine separators ensure excellent compressed air quality. Quick access service points allow servicing to be conducted with the minimum downtime and service costs. A water-cooled option is available on all fixed speed machines - L90 to L250. AirStation A lubricated screw compressor, receiver mounted with refrigerant dryer.

The complete packaged solution. Simple to Use - All components are perfectly matched and ready to 'Plug and Play'. Simple to Install - Ease and low cost installation. High Quality Receiver - Receivers built to the highest standard are inspection free for up to 5 years. Minimum Footprint - By mounting the components on the receiver, the required floor space is reduced by 55%. 50Hz, CE Approved Compressor Solutions The GD rotary screw compressor range from 2.2 – 500 kW, are designed to meet the highest requirements which the modern work environment and machine operators place on them. As a result, the GD compressors are extremely energy efficient, quiet and reliable.

These compressors continue to further strengthen Gardner Denver’s success story – variable and fixed speed compressor technologies available. Fixed Speed ESM 2-6 Series (2.2 - 7.5 kW) The easy and flexible solution - just smart! The compact design of the ESM series allows you to install the package quickly and efficiently. Based on customer requirements, these compressors can be supplied with many special options to provide a complete compressor station:.

As tankmounted version. As tankmounted version incl. Add-on refrigerant dryer.

As tankmounted version incl. Add-on refrigerant dryer and filter kit. As Premium package with Star/Delta starting and AirBasic controller (4 + 5.5 kW models). ESM 6 with AirBasic2 controller has four easy-to-use operating buttons including easy adjustment of pressure via the controller Your benefits in a nutshell:. Specially designed for small kW applications. Low noise level. Great Preformance.

No energy costs & no service costs for idle running hours. Compressors stops at max. Pressure Technical-Fixed Speed ESM 2-6 Series (2.2 - 7.5 kW) pdf/.pdf Fixed Speed ESM 7-22 Series (7.5-22kW) The ESM 7-22 fixed and variable speed screw compressors are designed to meet the high requirements which the modern work environment and machine operators place on them. As a result, our belt driven ESM VS 7–22 compressors are extremely energy efficient, quiet, reliable and easy to use, ensuring long operating life and delivery of optimal air quality.

The basic ESM VS 7-22 compressors can be equipped with useful options to meet even the toughest demands for building up a flexible compressor station. Technical-Fixed Speed ESM 7-22 Series (7.5-22kW) pdf/.pdf Fixed Speed ESM 23-29 Series (22 - 30 kW) Complete and enhanced offering between 22kW and 30kW Developed in direct response to market requirements, the new ESM 23-29 compressors introduce a number of new compressor sizes to the Gardner Denver range. This means that customers can now select the optimum compressor size for their application, improving installation efficiency and thereby reducing energy consumption and cost of ownership. Technical-Fixed Speed ESM 23-29 Series (22 - 30 kW) pdf/.pdf Fixed Speed ESM 30-132 Series (30-132kW) The ESM 30-132 series is specifically designed to meet the demands for continuous 24-hour use and absolute uptime, as required in critical industrial processes. Technical-Fixed Speed ESM 30-132 Series (30-132kW) pdf/.pdf Fixed Speed ESN/ESD 160-500 Series (160 - 500 kW) The preferred choice for optimum performance This compressor series combines Gardner Denver’s design philosophy, advanced DigiPilot controller and innovative package layout with efficient and reliable compressor performance.

As all Gardner Denver’s compressors, this series has rapidly become a popular choice for a wide range of demanding industrial applications. The compressor carries all Gardner Denver features and benefits associated with reliable and easy use and operation, and high efficiency. These compressors are specifically built to meet the demands of continuous 24/7 operating demands and absolute uptime. Your benefits in a nutshell:. Advanced DigiPilot control system. Serviceability. Robust design.

Low noise level operation. Great performance specifically built to meet the demands of continuous 24/7 operating demands and absolute uptime. Technical-Fixed Speed ESN/ESD 160-500 Series (160 - 500 kW) pdf/.pdf.

The new L-Series from CompAir Well known in the industry for quality and reliability, CompAir continuously develops the L-Series achieving cutting edge performance and efficiency. The new versatile range from 30 to 45 kW can be configured to meet the customers’ efficiency requirements. The E-models feature a larger airend delivering highest efficiency levels. The regulated speed models save energy by matching the output to the plant air demand.

All fixed speed models are available with integrated dryer option. Benefits An investment that pays off The E-Models of the L-Series feature an extra large airend with optimised rotor tip speed achieving up to 6% energy savings. The largest cost component of a compressor is the energy to run it. The reduction of energy costs significantly impacts on the total costs of ownership. The additional investment costs for this range of super efficient compressors will pay back in many cases in less than 12 months. The extra large airend also has a longer life expectancy. Regulated speed compressors The regulated speed models can efficiently and reliably handle the varying air demand found in most plant air systems.

The annual cost of ownership can be significantly reduced using regulated speed technology. CompAir RS features are your benefits. The L-RS Series products are designed to obtain the greatest efficiency across the entire operating range. Wide regulation range – No cycles means substantial energy savings.

Perfect motor – drive – airend design – High efficiency across broad flow range. Design Exceptional reliability and performance. Large surface after cooler Optimum cooling to ensure low operating and discharge temperatures. Next generation separator filter Amply dimensioned filtration for constant performance throughout the lifetime delivering an oil carryover of less than 3ppm. High efficiency electric motor The compressors are equipped with an energy saving IE4 electric motor as standard.

Thermostatically controlled motor driven fan Highly efficient and extremely quiet fan allows compressor operation in the work place, plus the use of maximum duct length without further assistance. Highest quality connections Solid hoses and pipe connections with viton victaulic couplings increase reliability and are easy to maintain. Controller Delcos XL innovative touch screen compressor controller The Delcos XL with its high resolution touch screen display is extremely user-friendly and self-explanatory. All functions are clearly structured in five main menus and are intuitively visual.

The multilingual Delcos XL control system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, which is essential for reducing your running costs. Features & functions. Home Page – instant overview of the compressor status. Real Time Clock – allows pre-setting of compressor starting/stopping. Second Pressure Setting.

Integrated Cooling and Dryer Control. Fault History Log – for in-depth analysis. Remote Control via Programmable Inputs.

Auto Restart after Power Failure. Optional Base Load Sequencing.

SD Card – stores several run characteristics CompAir L-Series – Technical Data L30 – L45 Fixed Speed. mm L30RS 5-10 30 1.33 – 5.53 66 925 1722 x 920 x 1659 L37RS 5-13 37 1.41 – 6.90 67 952 1722 x 920 x 1659 L45RS 5-13 45 1.41 – 8.02 70 974 1722 x 920 x 1659 1 Data measured and stated in accordance with ISO 1217, Edition 4, Annex C & E at the following conditions: Air Intake Pressure 1 bar a, Air Intake Temperature 20°C, Humidity 0% (Dry) 2 Measured in free field conditions in accordance with the ISO 2151, tolerance ± 3dB(A) 3 Data refer to ISO 7183, working pressure of 7 bar, inlet temperature 35°C and ambient temperature °C.

Comments are closed.

The new L-Series from CompAir

Well known in the industry for quality and reliability, CompAir continuously develops the L-Series achieving cutting edge performance and efficiency.

The new versatile range from 30 to 45 kW can be configured to meet the customers’ efficiency requirements. The E-models feature a larger airend delivering highest efficiency levels. The regulated speed models save energy by matching the output to the plant air demand. All fixed speed models are available with integrated dryer option.

Benefits

An investment that pays off

The E-Models of the L-Series feature an extra large airend with optimised rotor tip speed achieving up to 6% energy savings.

The largest cost component of a compressor is the energy to run it. The reduction of energy costs significantly impacts on the total costs of ownership.

The additional investment costs for this range of super efficient compressors will pay back in many cases in less than 12 months. The extra large airend also has a longer life expectancy.

Regulated speed compressors

The regulated speed models can efficiently and reliably handle the varying air demand found in most plant air systems. The annual cost of ownership can be significantly reduced using regulated speed technology.

CompAir RS features are your benefits.

The L-RS Series products are designed to obtain the greatest efficiency across the entire operating range.

Wide regulation range – No cycles means substantial energy savings.

Perfect motor – drive – airend design – High efficiency across broad flow range.

Design

Exceptional reliability and performance

- Large surface after cooler

Optimum cooling to ensure low operating and discharge temperatures. - Next generation separator filter

Amply dimensioned filtration for constant performance throughout the lifetime delivering an oil carryover of less than 3ppm. - High efficiency electric motor

The compressors are equipped with an energy saving IE4 electric motor as standard. - Thermostatically controlled motor driven fan

Highly efficient and extremely quiet fan allows compressor operation in the work place, plus the use of maximum duct length without further assistance. - Highest quality connections

Solid hoses and pipe connections with viton victaulic couplings increase reliability and are easy to maintain.

Controller

Delcos XL innovative touch screen compressor controller

The Delcos XL with its high resolution touch screen display is extremely user-friendly and self-explanatory. All functions are clearly structured in five main menus and are intuitively visual. The multilingual Delcos XL control system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, which is essential for reducing your running costs.

Features & functions

- Home Page – instant overview of the compressor status

- Real Time Clock – allows pre-setting of compressor starting/stopping

- Second Pressure Setting

- Integrated Cooling and Dryer Control

- Fault History Log – for in-depth analysis

- Remote Control via Programmable Inputs

- Auto Restart after Power Failure

- Optional Base Load Sequencing

- SD Card – stores several run characteristics

CompAir L-Series – Technical Data

L30 – L45 Fixed Speed

| Compressor | Nominal Pressure | Drive Motor | FAD1] [m3/min] | Noise [dB(A)] | Weight | Dimensions L x W x H | Integrated Dryer Option | Pressure dew [oC] | Weight |

|---|---|---|---|---|---|---|---|---|---|

| L30 | 7.5 10 | 30 | 5.75 5.01 | 67 | 887 | 1722 x 920 x 1659 | F30E (L30F) | 3 | 110 |

| L37 | 7.5 10 | 37 | 7.00 6.17 | 68 | 912 | 1722 x 920 x 1659 | F45E (L37F) | 3 | 120 |

| L45 | 7.5 10 | 45 | 8.00 7.00 | 69 | 953 | 1722 x 920 x 1659 | F45E (L45F) | 3 3 | 120 |

L30e – L45e Efficiency version, fixed speed

| Compressor | Nominal Pressure | Drive Motor | FAD1] [m3/min] | Noise [dB(A)] | Weight | Dimensions L x W x H | Integrated Dryer Option | Pressure dew [oC] | Weight |

|---|---|---|---|---|---|---|---|---|---|

| L30e | 7.5 10 | 30 | 6.00 | 67 | 954 | 1722 x 920 x 1659 | F30E (L30F) | 3 | 110 |

| L37e | 7.5 10 | 37 | 7.12 | 67 | 979 | 1722 x 920 x 1659 | F45E (L37F) | 3 | 120 |

| L45e | 7.5 10 | 45 | 8.67 | 67 | 1020 | 1722 x 920 x 1659 | F45E (L45F) | 4 3 | 120 |

L30RS – L45RS Regulated speed

| Compressor | Nominal Pressure | Drive Motor | FAD1] Min – Max | Noise Level2] at 70% load | Weight [kg] | Dimensions [mm] |

|---|---|---|---|---|---|---|

| L30RS | 5-10 | 30 | 1.33 – 5.53 | 66 | 925 | 1722 x 920 x 1659 |

| L37RS | 5-13 | 37 | 1.41 – 6.90 | 67 | 952 | 1722 x 920 x 1659 |

| L45RS | 5-13 | 45 | 1.41 – 8.02 | 70 | 974 | 1722 x 920 x 1659 |

Compair L37 Operation Manual Free

1 Data measured and stated in accordance with ISO 1217, Edition 4, Annex C & E at the following conditions:

Air Intake Pressure 1 bar a, Air Intake Temperature 20°C, Humidity 0% (Dry)

2 Measured in free field conditions in accordance with the ISO 2151, tolerance ± 3dB(A)

Compair L37 Operation Manual Pdf

3 Data refer to ISO 7183, working pressure of 7 bar, inlet temperature 35°C and ambient temperature °C.